In industries where handling hazardous materials is an unavoidable part of everyday operations, ensuring the safe and secure storage of dangerous goods and gas bottles is paramount. Trafalgar Safety, a trusted name in safety solutions, provides expert tips to enhance the safety measures associated with dangerous goods storage and gas bottle storage.

Understanding the Risks:

Before exploring storage options, it is essential to understand the hazards associated with managing hazardous substances and gas cylinders. It is crucial to recognize the distinct attributes of the materials, establish accurate categorization, and adhere to proper handling procedures as per the relevant Australian Standards.

- AS1940:2017 – The storage and handling of Flammable and Combustible liquids

- AS82187:199 – Explosives – Storage, transport and use

- AS2714:2008 – The storage and handling of Organic Peroxides

- AS 3780:2008 – The storage and handling of Corrosive substances

- AS4326:2008 – The storage and handling of Oxidising substances

- AS4332:2004 – The Storage and handling of gases in cylinders

- AS4452:1997 – The storage and handling of Toxic Substances

Compliance with Regulations:

Strict adherence to regulatory standards is imperative when storing hazardous substances and gas cylinders. It is advised to stay abreast of local and international regulations dictating storage procedures. Compliance not only guarantees safety but also mitigates the risk of legal complications.

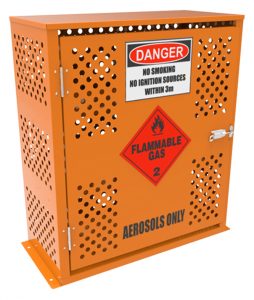

Specialized Storage Solutions:

Investing in specialized storage facilities designed for dangerous goods and gas bottles is a proactive measure. Trafalgar Safety offers a range of state-of-the-art storage solutions, including cabinets with proper ventilation, suitably fire-resistant materials, and secure locking mechanisms to prevent unauthorized access. Innovative hold-open devices and concealed mechanisms also help to ensure safety and ergonomics when loading and unloading materials.

Proper Ventilation Systems:

For gas bottle or aerosol storage, adequate ventilation is crucial to disperse any potential leaks or fumes. Trafalgar Safety advises the installation of ventilation systems that meet industry standards, preventing the buildup of hazardous gases and ensuring a safe working environment. This works in tandem with a suitable storage cage, which reduces risk of tip overs or mechanical damage to ensure a safe and compliant workplace.

Segregation and Labeling:

Segregating various categories of hazardous materials and marking storage zones are foundational practices. This underscores the importance of employing colour-coded labels and signage to facilitate straightforward identification, thereby reducing the chances of accidental exposure or incompatible substance reactions. Separation distances can be required to escape paths, other goods, or work areas – Consult the appropriate standard for information on required segregation distances.

Employee Training:

Ensuring that employees receive thorough training in the handling and storage of hazardous materials is crucial for accident prevention. Implementing comprehensive training programs is essential to educate personnel about the specific risks linked to different materials and the correct procedures for storage and handling.

Regular Inspections and Maintenance:

To ensure the continuous safety of storage facilities, it is imperative to conduct regular inspections and maintenance. This involves periodic examinations for leaks, damages, or any indications of wear and tear. Timely maintenance helps ensure the resilience and security of storage units.

Emergency Response Preparedness:

No matter how secure the storage may be, having a well-defined emergency response plan is imperative. Trafalgar Safety encourages businesses to conduct regular drills, ensuring that employees are familiar with emergency procedures in the event of spills, leaks, or other unforeseen incidents.

In conclusion, the collective responsibility for ensuring safety in dangerous goods storage and gas bottle storage cannot be overstated. Trafalgar Safety, with its unwavering commitment and expertise in delivering superior solutions, emphasizes the critical significance of embracing thorough safety measures. Contact us to gain insights on understanding risks, complying with regulations, investing in specialized storage, and prioritizing employee training. By incorporating these measures, businesses can establish a secure environment for handling dangerous goods and gas bottles, effectively minimizing risks and safeguarding the well-being of both personnel and the surrounding community.